Marek,

Topic is posted under the QCAD Pro forum ...

Rather a topic for the QCAD/CAM forum:

https://www.qcad.org/rsforum/viewforum.php?f=74

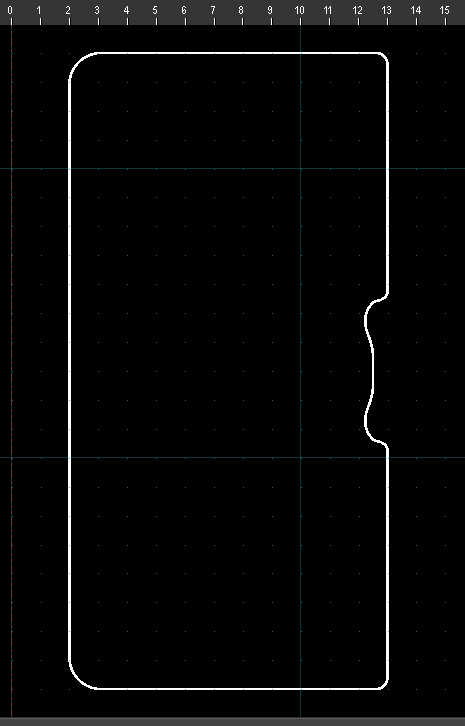

For reproducing this we need the DXF file, the source before CAM or the DXF saved after adding profiles with QCAD/CAM.

It is probably not spline related ...

G90/91

G90/91 is included in several postprocessors.

But not in

GCodeMM.js based on

GCodeBase.js.

GCodeMM.js aka

G-Code (G41/G42) [mm] is a generic postprocessor suited for the most basic G-Code interpreters.

You might want to select a more specific postprocessor depending your setup.

Or add a new custom postprocessor based on

GCodeMM.js or the best suited.

Don't forget to alter the

displayName &

description if you define a custom one.

(Never alter standard postprocessors shipped with QCAD/CAM as these are replaced each new update)

F0 would mean that you did not specify the Feedrate for a tool or for the toolpath.

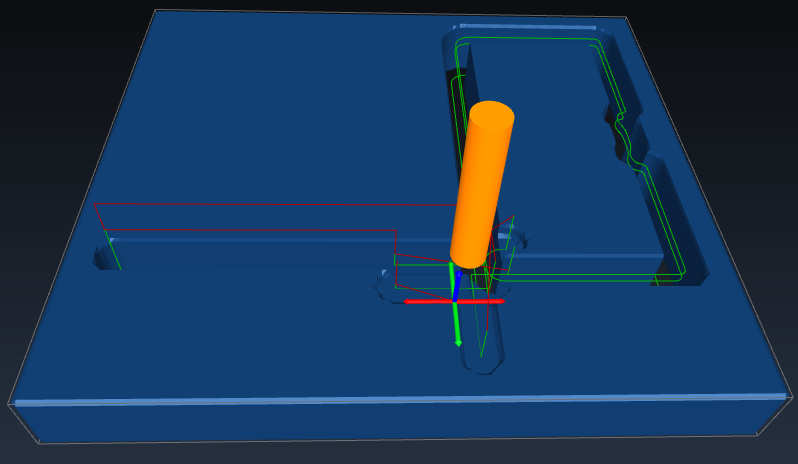

The crossing ends (lower middle) are presumed to be a Lead In/Out.

Mostly mandatory with G41/G42.

Use

GCodeOffsetIN.js or

GCodeOffsetMM.js as base to let QCAD/CAM calculate an offset path without G41/G42.

Or simply include

this.outputOffsetPath = true in your custom postprocessor.

The extension to the left is probably just a far traverse to a plunge and back up where there is a dot or Null-Length entity.

You probably have not configured 'Save Z' very well as it cuts shallow while traversing (lower red trajectory).

Or the tool length that the simulator uses is probably a default ...

QCAD/CAM does not account for tool length or any compensation of that.

The main idea is that Z = zero correlates with the top of your material.

'Save Z' should be positive, above the substrate, 'Cut Depth' is that too in QCAD/CAM settings but the G-Code Z would be negative.

To account for tool length you also need to zero your setup in Z on the top of your material, usually best after zeroing it in X-Y.

How simulators handle this work zero depends ...

Marek C wrote: ↑Thu Mar 21, 2024 12:27 am

As this is quite a soft and thin material (similar to ABS) I think one pass is sufficient.

Probably yes but have you considered that the shape will be floating free near the end of the cut?

When milled out as such your part can be pushed away or even grabbed by the cutter

This is more of an issue when milling than with laser cutting but still ...

Or use a vacuum table, a sticky work-pad, double sided tape, ...

Or add retaining TABs see CAM menu .. Add Tab (

KT)

Regards,

CVH

.

.