Hi and welcome to the QCAD forum.

Please specify your QCAD/CAM (trial) version.

Please attach a CAM drawing file

(Read lower 'Why') and the exported G-Code file.

There should be a major difference between: 'On path', calculated offset path or cutter compensation path.

The postprocessor

LinuxCNC [mm] is expected to use G41/42 cutter compensation.

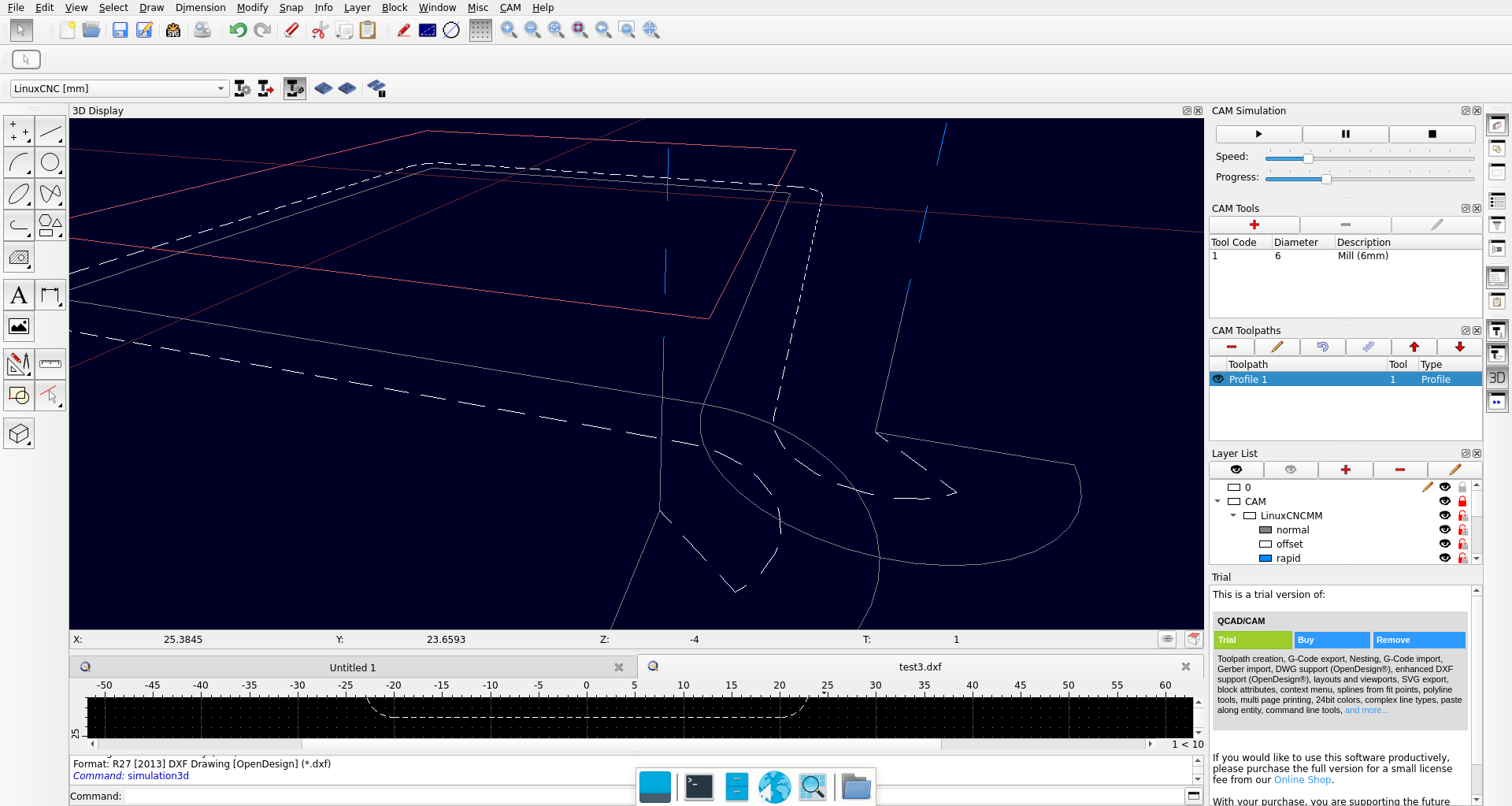

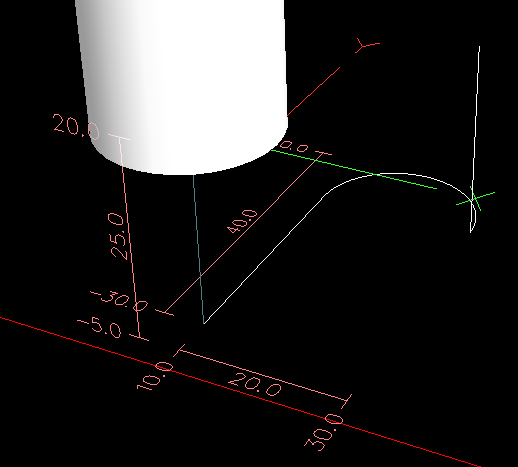

The Arcs of the red trajectories drawn at 10 units from the green shapes are correct entry moves for a calculated offset path.

With G41/42 active it is the green shape that is exported in G-code, when not it is the red path.

For G41/42 the driver internally calculate the required left or right center trajectory of your cutter.

There is no detailed information send back that you can visualize.

QCAD/CAM only visualize the expected central path ...

The motions to the Arc center in the 3D Display are already very odd

But they can be considered as correct compensation moves along a straight pre-entry move.

Why that is not tangent to the start of the circular entry move remains open.

The general idea is to smooth the motions and avoiding hard corners where possible.

It is indeed problematic with (additional) circular entry moves.

Something similar was already addressed in

FS#2558 and related forum topic

t10724.

With cutter compensation:

Attached to

FS#2558 is a snippet of a document that explains to use a straight pre-entry move.

Because it is NOT POSSIBLE to compensate an Arc entry gradually with another Arc-like path.

Most drivers can not cope with the true trajectory of offsetting an Arc from zero to R

cutter along the Arc.

Supported G-code is typically limited to G0, G1, G2 or G3.

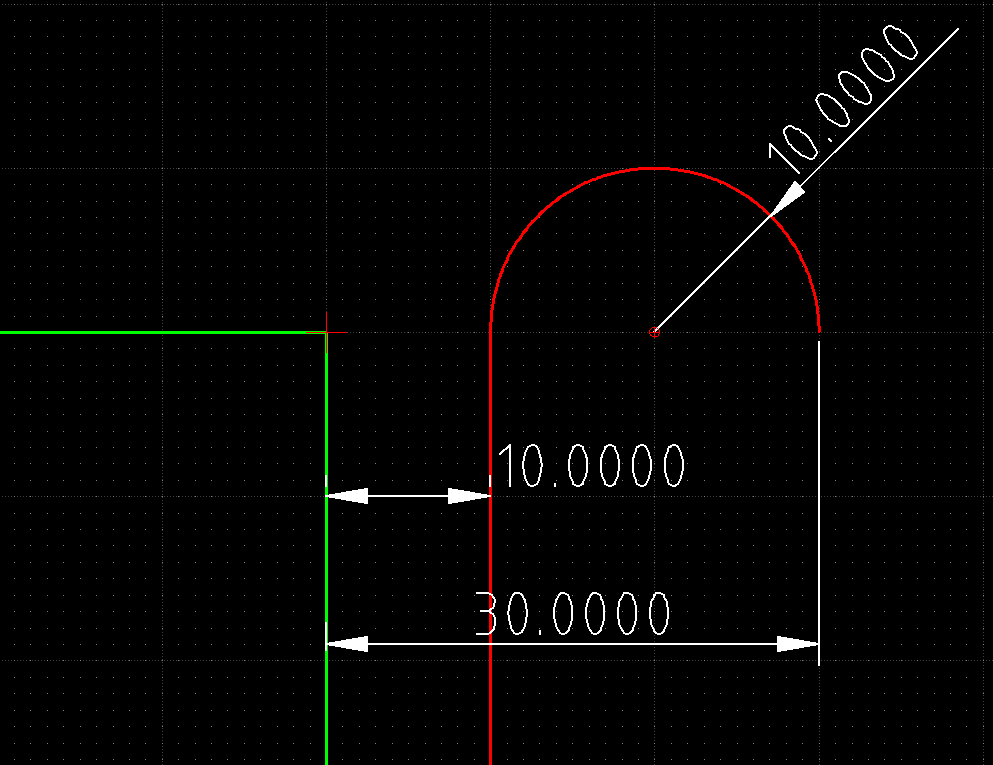

- G41-Arc compensation.png (11.49 KiB) Viewed 18808 times

In the above the blue arc is a 3 point arc connecting the compensated cutter centers at 0-45-90°.

It doesn't connect tangentially to the horizontal blue path and doesn't match with other cutter center positions.

The bulge of the blue central path would result in an over-cut for the entry path

In magenta I added 1/4 of an ellipse, the only shape that will be tangent at start and end but it doesn't match with any other center position.

The true trajectory that connects the compensated cutter centers is a part of some spiral function.

Typically UNSUPPORTED.

Common in G41/42 trajectory visualization is that the center path and the edge of the cut area start at the same point.

As if the cutter grows from R=zero to R=R

cutter along the entry trajectory.

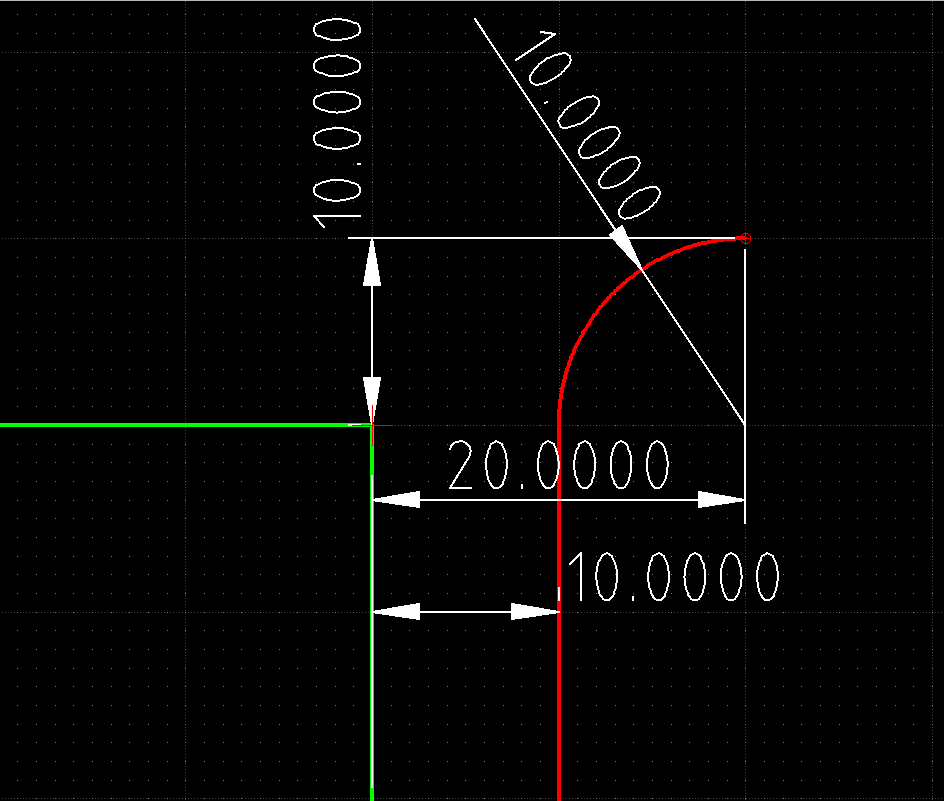

I find the visualization of curved compensation paths in QCAM incorrect or at least misleading.

An offset to those central paths by R

cutter may even result in over-cutting.

A hunch ... I can not verify that with my CNC setup.

'As is' QCAD/CAM only supports plunging straight down and cylindrical cutters.

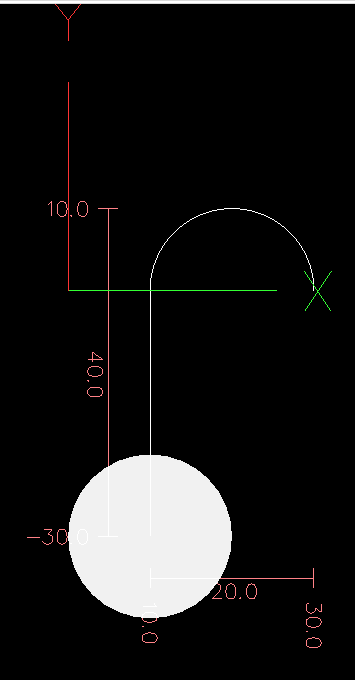

Plunging at the start of the entry move results in the orange dotted representation of the cutter.

The cutter edge is not matching with the cut area in white

Plunging at the end of the entry move is no longer a circular motion that gradually approaches the area to cut

Only plunging after a straight pre-entry move is correct.

Calculated offset:

My CNC driver fails critical and displays a warning for an initial Arc-entry in combination with G41/42.

What limits my personal use of QCAD/CAM to a calculated offset path.

Then the center path and the edge of the cut area should NEVER start in the same point

In the related topic there are several examples of false trajectories (also called 'donkey ears') and the proper representations.

FS#2558 was rejected and closed based on '

No DXF file provided'.

(Why)

But 3 months later, for a similar report

t10951 a new Bug Report

FS#2584 was opened by Andrew himself and later resolved.

Milling 'On path':

Basically nothing more than adding circular motions at start and end.

But it is debatable if that is still 'On path' and it is unclear from which side that should approach the drawn path.

Curved entry paths at corners is also debatable.

They are usually added where you approach a face to mill.

Regards,

CVH